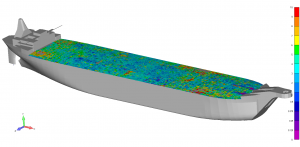

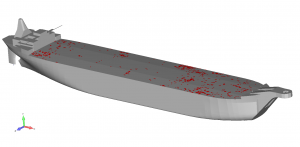

During FEED, hull conversion, or life-extension projects, SAGA applies corrosion gaugings entered into a database system developed by Viking. The system uses a 3D model to show gaugings for plates and the webs and flanges of stiffeners. It also carries out a complete steel renewal procedure using class-required substantial thickness calculations, future corrosion projections, and required steel renewal. These are shown graphically on a 3D model. The following are also shown:

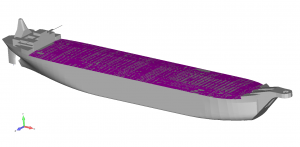

SAGA applies the corrosion values by subtracting FEA model scantlings, which include:

The model’s gauging database is compared, and a corroded model is made. The following also take place:

Resulting FEA model with as-gauged thickness:

326 First Street

Suite 36

Annapolis, MD 21403

525 S Flagler Drive

Suite 27D

Palm Beach, FL 33401

Aarhusgade 118

2150 Copenhagen

Denmark

3 Fusionopolis Place

#05-53

Singapore 138523